Belt Conveyor Drive Head Bend Take up Snub Wing Tail Ceramic Rubber Coated Diamond Herringbone Chevron Grooved Lagging Crowned Motorized Drum Pulley for Mining

A conveyor will always consist of at least two pulleys, head pulley and tail pulley, with additional pulleys used depend

Basic Info

| Model NO. | CEMA DIN AFNOR JIS FEM BS |

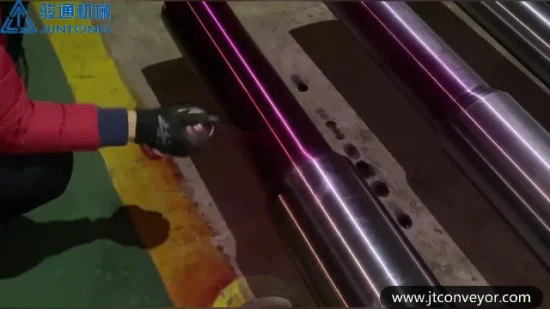

| Rubber Lagging | Ceramic/Smooth/Diamond/Herringbone/Polyurethane |

| Pulley Lagging Type | Hot Vulcanized and Cold Adhesive |

| Light Connection Mode | The Shaft and Hub Are Single-Width Plate Welded Cy |

| Medium Connection Mode | The Shaft and Hub Are Expansion Sleeve Connection |

| Balance Treatment | Dynamic Balance and Static Balance |

| Pulley Structure | Tube/Shaft/Bearing/Bearing Block/Hub/Bushing |

| Bearing Type | Self-Aligning Ball Bearings |

| Bearing Band | Hrb/NSK |

| Welding | Submerged Arc Welding |

| Shaft Material | 45# Steel/40crmnmo/Stainless Steel |

| Tube Material | Q235/Q355/J355/Ss400/Stainless Steel |

| End Disc Material | Cast Iron/Cast Steel/Zn35 |

| Rubber Hardness | 60/65/70 Shore |

| Transport Package | Wooden Box Packing and Pallet Packing |

| Specification | BW650, BW800, BW1000, BW1200, BW1400, BW1600, |

| Trademark | KONWEYOUR |

| Origin | Hengshui, China |

| HS Code | 8431390000 |

| Production Capacity | 3000 Pieces Per Month |

Product Description

A conveyor will always consist of at least two pulleys, head pulley and tail pulley, with additional pulleys used depending on the configuration. Standard-duty pulleys are usually adequate for simple applications, but mine-duty and engineered pulleys are also available where heavy-duty pulleys are required.Different kinds of conveyor pulleysKONWEYOUR® sells conveyor pulleys in all the following sub-categories: Head pulleysThe head pulley is located at the discharge point of the conveyor. It usually drives the conveyor and often has a larger diameter than other pulleys. For better traction, the head pulley is usually lagged (with either rubber or ceramic lagging material).Tail and wing pulleysThe tail pulley is located at the loading end of the belt. It comes with either a flat face or a slatted profile (wing pulley), which cleans the belt by allowing material to fall between the support members.Snub pulleysA snub pulley improves the traction of the drive pulley, by increasing its belt wrap angle.Drive pulleysDrive pulleys, which can also be the head pulley, are driven by a motor and power transmission unit to propel the belt and material to the discharge.Bend pulleysA bend pulley is used for changing the direction of the belt.Take-up pulleyA take-up pulley is used to provide the belt with the proper amount of tension. Its position is adjustable.

| Type | Belt width(mm) | Standard Diameter(mm) | Length(mm) |

| Drive Pulley | 500 | 500 | Length of the pulley depends on the belt width of the conveyor |

| 650 | 500~630 | ||

| 800 | 630~1000 | ||

| 1000 | 800~1150 | ||

| 1200 | 800~1150 | ||

| 1400 | 1000~1350 | ||

| 1600 | 1150~1600 | ||

| 1800 | 1150~1800 | ||

| 2000 | 1350~2000 | ||

| 2200 | 1600~2200 | ||

| 2400 | 1800~2400 | ||

| Bend Pully | 500 | 250~500 | |

| 650 | 250~630 | ||

| 800 | 250~1000 | ||

| 1000 | 250~1600 | ||

| 1200 | 250~1600 | ||

| 1400 | 315~1600 | ||

| 1600 | 400~1600 | ||

| 1800 | 400~1600 | ||

| 2000 | 500~1600 | ||

| 2200 | 630~1600 | ||

| 2400 | 800~1600 |

Send to us