Precision Customized Transmission Gear Helical Gear for Various Machinery

Basic Info

| Model NO. | Transmission Gear |

| Application | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car |

| Hardness | Hardened Tooth Surface |

| Gear Position | Internal Gear |

| Manufacturing Method | All |

| Toothed Portion Shape | All |

| Material | on Request |

| Type | All |

| Quality | High-Quality |

| Size | Customerized |

| Transport Package | on Request |

| Specification | Customized |

| Origin | China |

| HS Code | 8483409000 |

| Production Capacity | 55, 000 PCS/Year |

Product Description

High Precision Customized Transmission Gear Helical Gear for Various Machinery.Custom Plastic/Spur/Metal/Driver/Speed/Bevel/Helical/Worm Gear.

Custom Gears and Precision Small Module Gear Small Spur Gear

| Any other material and dimension depends on customers' demand. |

| Material: Steel / aluminum / brass / iron / zinc / alloy, etc. |

| Surface: As your requirement. |

| Produce according to with ISO, GB, DIN, standard. |

| OEM or according to customer's drawing and samples requirements. |

| Quality control in every process. |

| Small order is accepted. |

| High precision. |

| Comprehensive and efficient after-sale service. |

Our Product Range

| Material | Carbon Steel | SAE1020, SAE1045, Cr12, 40Cr, Y15Pb, 1214L. |

| Alloy Steel | 20CrMnTi, 16MnCr5, 20CrMnMo, 41CrMo, 17CrNiMo5... | |

| Brass/Bronze | HPb59-1, H70, CuZn39Pb2, CuZn40Pb2,C38000, CuZn40 | |

| Machining process | Gear Hobbing, Gear Milling, Gear Shaping, Gear Broaching, Gear Shaving, Gear Grinding and Gear Lapping | |

| Module | 1.0, 1.25, 1.5, 1.75, 2.0, 2.25, 2.5....8.0 | |

| Tolerance control | Outer Diameter: ±0.005 mm | Length Dimension:±0.05 mm |

| Teeth accuracy | DIN Class 4, ISO/GB Class 4, AGMA Class 14, JIS Class 0 | |

| Heat treatment | Quenching & Tempering, Carburizing & Quenching, High-frequency Hardening, Carbonitriding... | |

| Surface treatment | Blacking, Polishing, Anodization, Chrome plating, Zinc plating, Nickel plating... | |

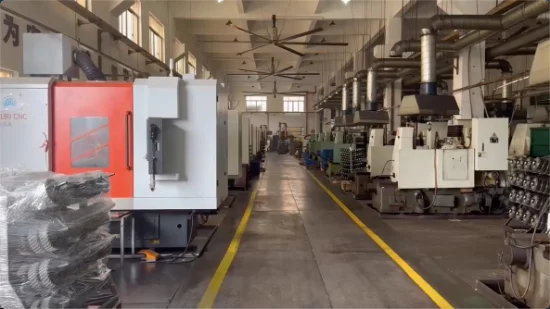

About Us

Top-end Industrial Manufacturing & Engineering Inc (TIME) was founded with the mission of supplying world class forging products at the best prices.We have a strong engineering team to ensure the quality stability for our customers' projects. All our engineers have more than 10 years of engineering experience and are specialized in metallurgy, forging, heat treatment, NDT, machining and production testing respectively.For any forging product, only if you supply a sample or operating requirements, our engineers will design the optimal forging process and subsequent testing or manufacturing process for your product.We have been achieving our mission and delivering the most cost-effective, highest quality solutions to our customers.Our quality control begins from raw material, forging, heat treatment, semi-finished machining, final machining till assembly, each step is controlled strictly by our engineers, all of them have 10+ years of engineering experience and are specialized in metallurgy, forging, heat treatment, NDT, machining and production testing respectively.