Pinion Rack Round Worm Screw Helical Hypoid Straight Ring Spiral Forged Bevel Spur Differential Steering Internal Box Spline Plastic Nylon Stainless Steel Gear

Basic Info

| Model NO. | Bevel Spiral Spur Helical |

| Application | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car, Industry |

| Hardness | Hardened Tooth Surface |

| Gear Position | External Gear |

| Manufacturing Method | Cast Gear |

| Toothed Portion Shape | Worm/Spur/Helical/Bevel |

| Material | Custom |

| Type | Custom |

| Processing Machine | CNC Machine |

| Material. | 20crmnti/ 20crmnmo/ 42CrMo/ 45#Steel/ 40cr/ 20crni |

| Heat Treattment | Carburizing and Quenching |

| Hardness. | 58-62HRC |

| Standerd | GB/ DIN/ JIS/ Agma |

| Transport Package | Wooden Case |

| Specification | Customize |

| Trademark | EPT or OEM |

| Origin | Zhejiang |

| HS Code | 8483900090 |

| Production Capacity | 50000PCS/Month |

Product Description

Pinion Rack Round Worm Screw Helical Hypoid Straight Ring Spiral Forged Bevel Spur Differential Steering Internal Box Spline Plastic Nylon Stainless Steel GearProduct Description

Click the picture to learn more

| Spur gear | Helical gear | Double helical gear herringbone gear |

| Miter gear | Spiral Bevel Gear | Straight bevel gear |

| Internal gear | Worm gear & worm shaft | Gear rack |

| Material | C45,40Cr,20CrMnTi,42CrMo, Copper, Stainless steel and so on as per your requests. |

| Processing | F.orging, Machining, Hobbing, Milling, Shaving, Grinding, Heat treatment....… |

| Heat Treatment | Carburizing,Induction,Flame,Nitriding....… |

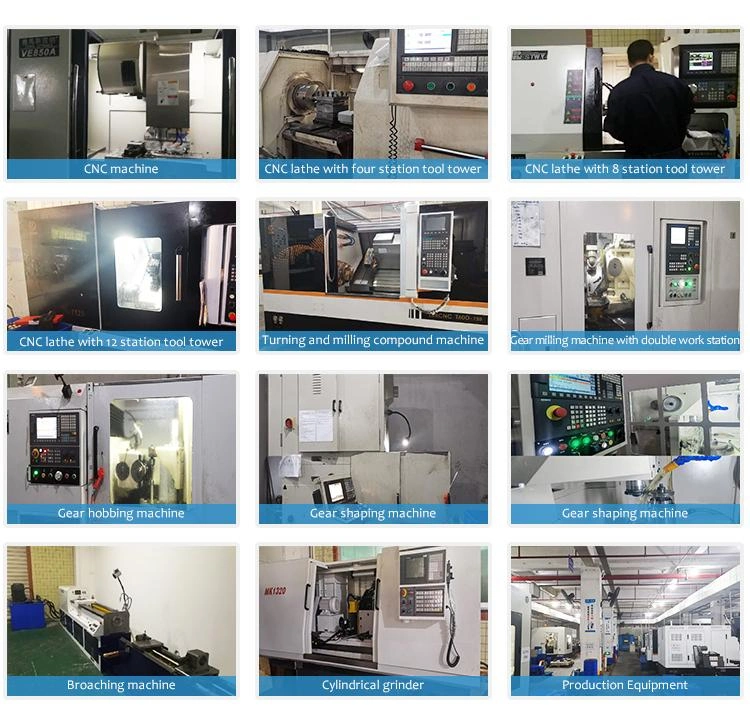

| Main Machines | NC Gear Hobbing Machines, NC Gear Shapers(Gealson, Moude), NC lathe, NC gear Shaving machines, NC gear milling, Nc gear grindingMachines and many kinds of gear related machines. |

Click here to get the latest quotation!

Related products:

Company Profile

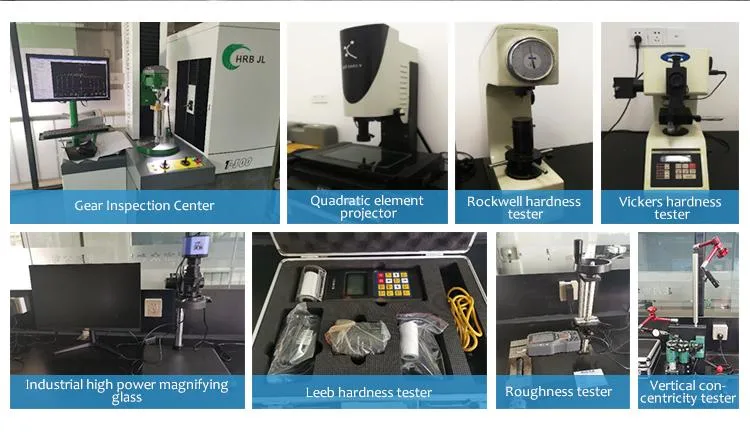

Our factory is mainly engaged in the manufacturing and processing of large and medium-sized straight teeth, helical teeth, bevel teeth, herringbone teeth and other gear transmission products. At the same time, we have also developed zinc based alloy wear-resistant materials that can replace copper products, with light weight, low cost and good performance. Our factory is equipped with high frequency, ultra audio frequency, large heat treatment equipment, complete gear making equipment, strict production process, and perfect detection means. Now we focus on developing: rubber chemical machinery gear; Gear of gold beneficiation machinery; Mechanical gear for metallurgical building materials; Hydraulic engineering machinery gear; Agricultural machinery gear; General reducer gear; There are more than 100 gear transmission varieties, such as gears, turbines, sprockets, etc. of the medical equipment supporting gear series. The supporting manufacturers are all over the province and abroad. Some products have been exported in batches and are highly praised by users.For a long time, our factory has always adhered to the principle of "no best, only better", and is willing to sincerely cooperate with domestic and foreign enterprises and merchants, develop and prosper with professional technology, sincere reputation and perfect service. We welcome friends to come for cooperation and exchange.

Our production equipments

Packaging and transportation