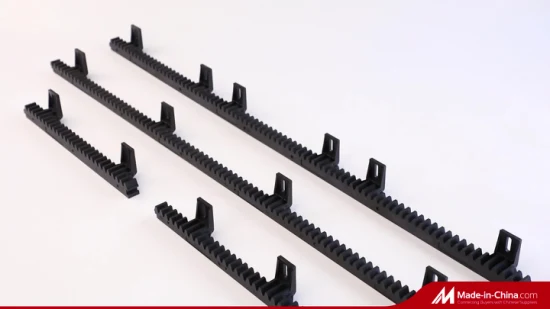

Chinese Standard Finished Bore Roller Chain Sprocket with Heat Treatment

Chinese standard finished bore roller chain sprocket with heat treatmentWith more than 20 years' experience, high-precis

Basic Info

| Model NO. | Standard |

| Standard Or Nonstandard | Standard |

| Application | Motor, Motorcycle, Machinery, Toy, Agricultural Machinery, Car |

| Hardness | Hardened Tooth Surface |

| Manufacturing Method | Forging Parts |

| Material | Carbon Steel |

| Teeth | 9t-120t |

| Sprocket Size | DIN8196/ISO606/JIS1802/GB1243 |

| Processing | Forging-Machining-Hobbing-Teeth Harden-Tempering |

| OEM | Scs Offers OEM Service |

| Lead Time | 45 Days After Advance Payment |

| Heat Treatment | High Frequency Induction Hardening and Tempering |

| Surface Treatment | as Required |

| Transport Package | Plywood Cases |

| Specification | DIN JIS ISO |

| Trademark | SCS |

| Origin | Changzhou, Jiangsu |

| HS Code | 8483900090 |

| Production Capacity | 5500000 Piece/Pieces Per Year |

Product Description

Chinese standard finished bore roller chain sprocket with heat treatmentWith more than 20 years' experience, high-precision equipment and strict management system, SCS can provide sprockets, gears, shafts, flanges and related transmission parts for you with stable quality and best service.Q1: What information will be highly appreciated for a quotation?

A: It will be preferred if you can offer us the drawings, heat treatment and surface treatment requirements, required quantity, quoted currency (USD or EUR), or samples.

Q2: Are you a trading company or factory?

A: SCS is a factory located in Changzhou, Jiangsu.

Q3: What is your terms of payment?

A: T/T 50% in advance, and 50% before shipment. We'll show you the photos of the products and packages before you pay the balance.

Q4: Do you test all your goods before delivery?

A: Yes, SCS has adopted a strict quality management system and all the items will be inspected according to the inspection instruction with good inspection records.

Q5: Is there any customer that has assessed your quality management system?

A:Yes, SCS has passed the audit of many customers, such as Mitsubishi, CLAAS, Kardex and so on.

Q6: How does your company ensure the quality of the raw material?

A: The steels are purchased from our domestic well-known steel mills. After receiving the raw material, the steel will be inspected by spectrograph imported from Germany. Besides, the furnace number of steel will be well-managed in our ERP system to ensure the traceablity of our products.

Q7: How do you ensure the high quality of products?

A: With integral manufacturing processes, a strict quality control system and imported machines, we can manufacture high quality products.

Q8: What are your terms of delivery?

A: EXW, FOB Shanghai.

Q9: How about your lead time?

A: Normally it will take 45 days after receiving your advance payment. The specific lead time depends on the items and the quantity of your order.

Send to us